In cooperation with renowned manufacturers of adhesive pads, SAR has automated the process of applying pads onto openings in car bodies.

SAR’s “automated process of sealing holes” is characterised by significantly higher precision levels and process monitoring compared to conventional methods.

Car bodies feature numerous openings required for the coating process. After completion of this process, these openings must be resealed reliably.

Up until now, this was done manually with so-called “paint plugs”. These are pressed into the openings manually where they lock into place.

The conventional solution

Challenges with the current manual insertion process using conventional paint plugs:

- The quality of the seal depends on the worker and cannot be reproduced

- The work stations prove to be ergonomically strenuous for the worker

- For each opening, a form-fitting plug must be selected and inserted manually. No process control is provided

- An inadequately sealed hole may lead to vehicle damage caused by corrosion

The solution offered by SAR

Renowned material manufacturers have developed sealing materials that allow for an automated sealing process.

By means of a robot, adhesive pads are accurately positioned over the holes at high speed and with a high degree of repeatability.

A proper overhang ensures stable and permanent adhesive bonding. As general contractor, SAR integrates a simple and functional solution into existing as well as new systems within the paint shop sector.

Serial production security ensured thanks to test set-ups and feasibility studies based on simulations

To be able to assure the highest level of safety and security to the customer in advance, SAR is carrying out a feasibility study based on a robot simulation.

Furthermore, SAR provides test set-ups. For this purpose, serial production material is applied onto the customer’s car bodies or test panels as part of material approval tests.

Implemented for the first time in 2017

In cooperation with FAIS ChemTec, SAR already developed an applicator for sealing holes in 2017 and implemented a system for the application of pads.

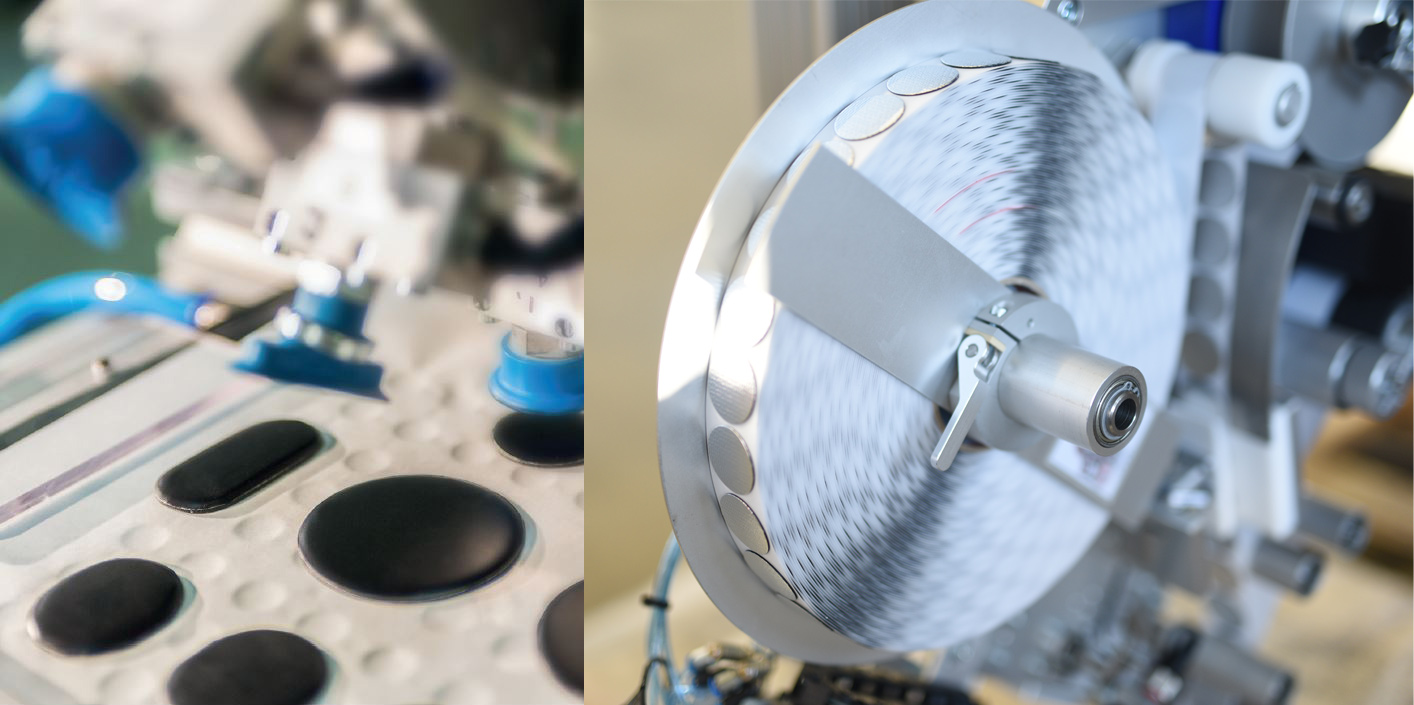

Since then, we have been continually developing the concept. Therefore, we are able to use new applicators of other manufacturers - such as the tesa® EfficienSeal - and apply tesa® Sealing Patches from the reel.

In 2019, for example, a series production project was carried out at Porsche.

Future potential

SAR sees great potential in the “automated sealing of holes”, as the previous processes have had negative ergonomic effects and quality risks. Costs can be reduced and quality improved with the SAR solution.

Projects realised up to now:

- Audi – serial system in production

- Porsche – serial system under development

- feasibility studies and test set-ups for diverse vehicles

For further information, please feel free to contact us at

ofs@sar.biz

“Automated sealing of holes” by SAR

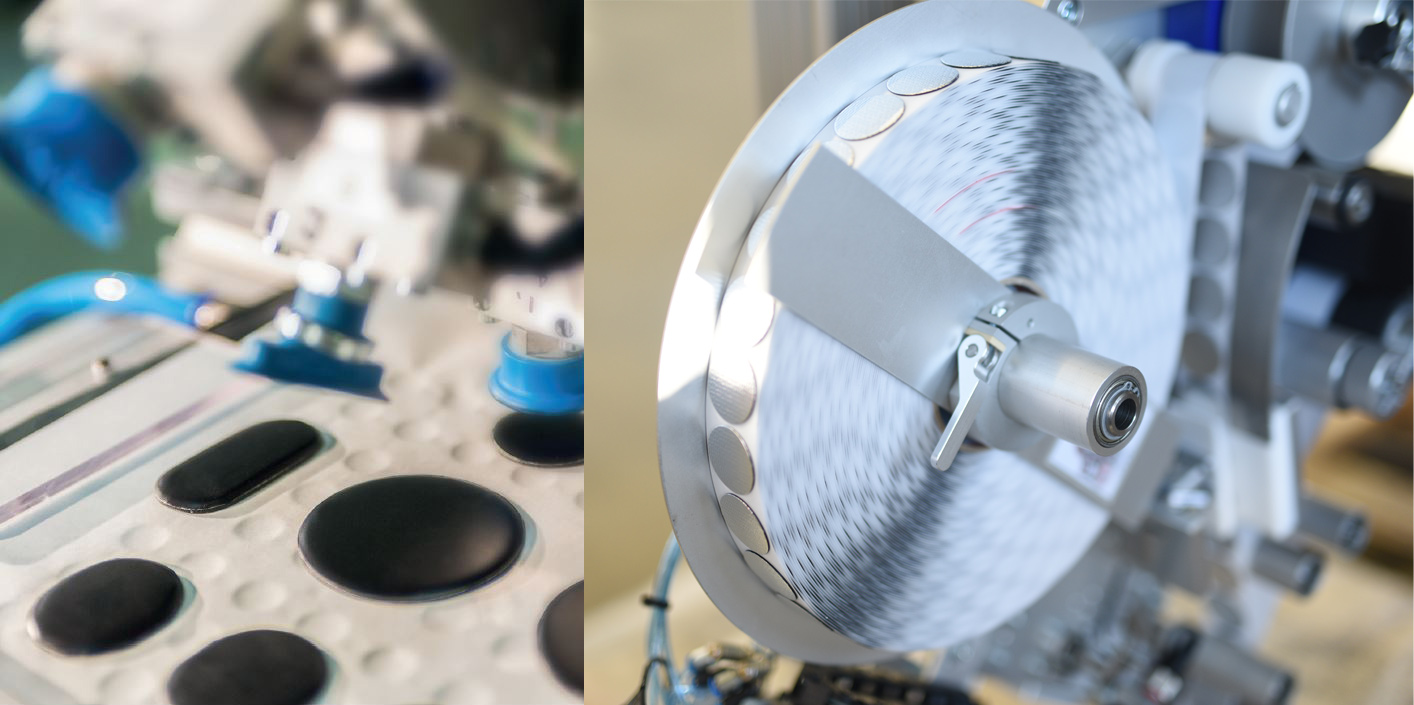

Uptake of the state-of-the-art adhesive pads by means of different material feed options:

on the left in the picture Alu-Butyl material and on the right, tesa® Fireguard sealing patches

Simulation of a cell

Example video with tesa applicator